Popular Types of Conveyor Chains Used in Modern Industrial Transportation Systems

In today’s industrial transportation systems, selecting the right type of conveyor chain is critical to optimizing operational efficiency, extending equipment lifespan, and ensuring safe, continuous production. Depending on the material handling requirements, work environment, and technical specifications, different conveyor chains are applied to meet specific needs in industrial systems.

This article explores the most commonly used types of conveyor chains in modern industrial transportation, helping businesses choose the most suitable solution for their operations.

Article content

The Important Role of Conveyor Chains in Industrial Transport Systems

- Conveyor chains enhance material handling efficiency, reducing dependence on manual labor.

- They ensure the safe and continuous transportation of heavy and bulky materials.

- Ideal for harsh working environments, including high temperatures, high humidity, and chemical exposure.

- Reduce maintenance costs and optimize long-term operating expenses.

Popular Types of Conveyor Chains in Modern Industrial Transport

1. Roller Chains

- Structure: Composed of links with rollers that reduce friction during operation.

- Advantages:

- High load capacity and smooth operation.

- Suitable for medium to high-speed conveyor systems.

- Applications: Industrial production lines, conveyors, packaging machines.

2. Bush Chains

- Structure: Consist of bushings and pins without rollers.

- Advantages:

- Simple design, easy to install and maintain.

- Operates well in harsh conditions with minimal maintenance.

- Applications: Agricultural equipment, construction machinery, material transport systems.

3. Bush Roller Chains

- Structure: A combination of bushings and rollers for enhanced load capacity and smoother operation.

- Advantages:

- Reduces wear when handling heavy materials.

- Stable operation in automated production lines.

- Applications: Cement plants, steel mills, heavy-duty industrial lines.

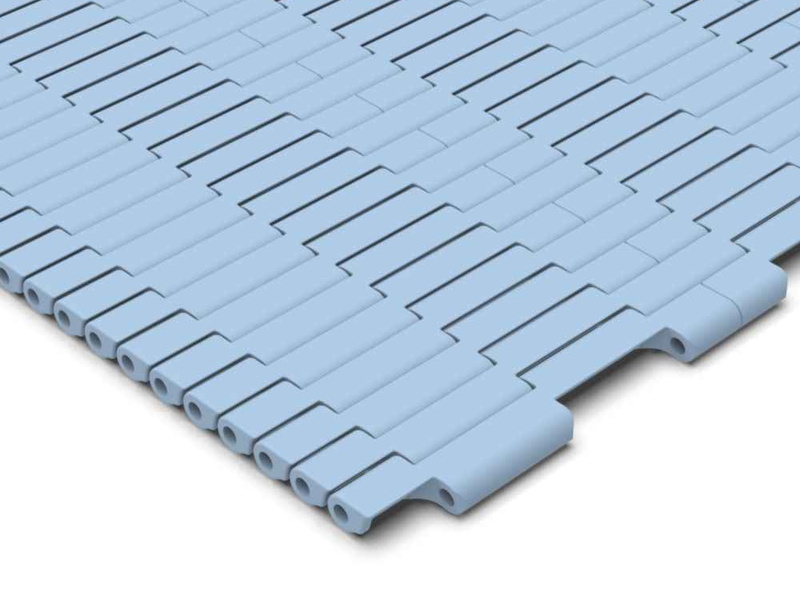

4. Flat Top Chains

- Structure: Links with flat tops that create a smooth surface.

- Advantages:

- Flat surface ideal for transporting fragile or unstable products.

- Easy to clean, suitable for the food and beverage industry.

- Applications: Beverage production plants, food processing, pharmaceutical packaging lines.

5. Conveyor Chains

- Structure: Flexible design with various link types to suit different conveyor systems.

- Advantages:

- Handles heavy loads efficiently.

- Available in various sizes and materials for specific applications.

- Applications: Warehouses, logistics centers, pallet transport systems.

6. Double Pitch Chains

- Structure: Links with twice the pitch length compared to standard roller chains.

- Advantages:

- Lighter weight, saving energy during operation.

- Cost-effective solution for medium to light-duty applications.

- Applications: Packaging lines, food conveyors, electronic component assembly.

7. Heat-Resistant Chains

- Structure: Made special alloy steel designed to withstand high temperatures.

- Advantages:

- Operates reliably at temperatures up to 400-500°C.

- Resists thermal expansion and rapid wear.

- Applications: Kilns, cement production lines, metallurgy and foundry industries.

Criteria for Selecting the Right Conveyor Chain for Industrial Transport Systems

- Load Capacity: Determine the weight of the materials to a chain with appropriate strength.

- Working Environment: Consider factors like temperature, humidity, and chemical exposure that may affect chain durability.

- Transport Speed: Choose a chain capable of stable operation at the required speed.

- Investment and Maintenance Costs: Evaluate the total cost, including installation, maintenance, and periodic replacement.

Conclusion

In modern industrial transportation, choosing the right conveyor chain not only improves production efficiency but also optimizes operating costs and reduces maintenance requirements in the long term. Each type of conveyor chain has its unique advantages and applications, tailored to specific industries and technical demands.

If your business is looking for optimal conveyor chain solutions for industrial transportation systems, contact us for professional consultation and competitive pricing.

.jpg)

.jpg)

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon