882 M LBP

4 5 (1 evaluate)Category: Belts

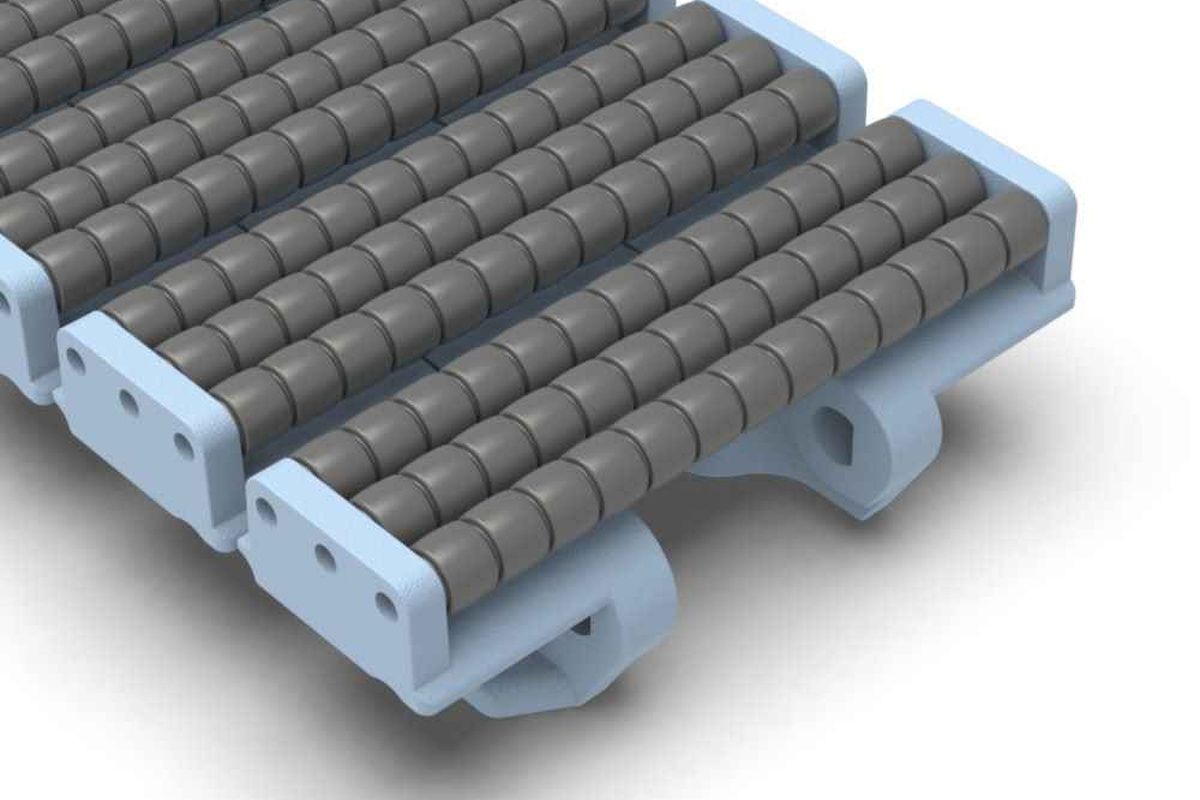

The 882 M LBP belt is specifically designed to meet the demands of stable and smooth goods transportation in modern automated systems. Featuring integrated low-friction rollers (LBP) and durable engineered plastic, this belt is ideal for industries such as food processing, pharmaceuticals, and component manufacturing.

1. What is the 882 M LBP Belt?

The 882 M LBP belt is a high-performance conveyor belt crafted from premium-engineered plastic with integrated low-friction rollers on the surface. This design reduces friction, enabling smooth transportation of goods, making it suitable for continuous and high-precision production lines.

2. Key Features of the 882 M LBP Belt

a. Integrated Low-Friction Rollers (LBP)

- The low-friction rollers on the belt surface minimize resistance, protect goods, and maintain steady transportation speed.

- Ideal for handling sensitive or easily scratched products.

b. High-Quality Engineered Plastic

- Made from durable plastic, the belt offers excellent wear resistance and high load-bearing capacity.

- Resistant to corrosion and mild chemicals, ensuring efficient operation in wet or chemically intensive environments.

c. High Load Capacity

- The 882 M LBP belt is designed to handle heavy loads, making it perfect for continuous and demanding operations.

d. Easy Installation and Maintenance

- Modular construction allows for quick assembly and replacement, reducing maintenance time and ensuring efficient operation.

3. Practical Applications of the 882 M LBP Belt

a. Food and Beverage Industry

- Packaging Lines: Ideal for transporting cans, bottles, and containers in automated packaging systems.

- Food Processing Systems: Meets hygiene standards, easy to clean, and suitable for beverages, confectionery, and frozen foods.

b. Pharmaceutical Industry

- Transporting Sensitive Products: Perfect for small pharmaceutical items like blister packs, vials, or medical devices, ensuring precision and safety.

- Automated Inspection Systems: Enhances efficiency in sorting, inspecting, and packaging processes.

c. Light Manufacturing

- Component Assembly Lines: Suitable for transporting electronic parts, automotive components, or small industrial devices.

- Lightweight Goods Transport: Provides stable handling for lightweight products requiring high precision and reduced friction.

4. Benefits of Using the 882 M LBP Belt

a. Reduces Friction

- Integrated low-friction rollers minimize resistance, protect goods, and ensure smooth transportation.

b. Improved Operational Efficiency

- Optimized design ensures smooth and uninterrupted operation, reducing downtime and optimizing productivity.

c. Cost-Effective Solution

- Durable materials minimize maintenance and replacement costs, providing long-term savings.

d. Versatile Applications

- Suitable for various industries and products, from food and pharmaceuticals to industrial components.

5. Technical Specifications

| Model | Material | Width (mm) | Max Load (N) | Key Applications |

|---|---|---|---|---|

| 882 M LBP W80 | Engineered plastic + rollers | 80 | 2,500 | Food packaging, beverages |

| 882 M LBP W140 | Wear-resistant plastic + rollers | 140 | 2,500 | Pharmaceutical products |

| 882 M LBP W200 | High-strength plastic + rollers | 200 | 2,500 | Component assembly, light goods |

6. Comparison with Other Conveyor Belts

| Criteria | 882 M LBP Belt | 882 M Belt | 821 GT Belt |

|---|---|---|---|

| Friction Reduction | Excellent | Good | Moderate |

| Maximum Load Capacity | 2,500N | 2,500N | 2,770N |

| Key Applications | Food, pharmaceuticals | Packaging, lightweight goods | Industrial operations |

7. Installation and Maintenance

a. Installation Guidelines

- Ensure proper alignment of belt links and rollers to prevent misalignment or excessive wear.

- Use compatible sprockets and guide rails to optimize conveyor performance.

b. Maintenance Tips

- Regular Cleaning: Clean the belt surface and rollers to remove dirt and grease, ensuring smooth operation.

- Routine Inspections: Check for wear or damage on the links and rollers, replacing components as needed.

- Timely Replacements: Replace damaged parts promptly to maintain consistent performance.

8. Conclusion

The 882 M LBP belt is a modern and efficient solution for automated conveyor systems. With integrated low-friction rollers, durable plastic construction, and versatile applications, this belt enhances productivity, reduces operational costs, and ensures the safe transportation of goods. Investing in the 882 M LBP belt guarantees optimized performance and long-term savings for your production lines.

.png)

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon