HMF

4 5 (1 evaluate)Category: Chester Jensen

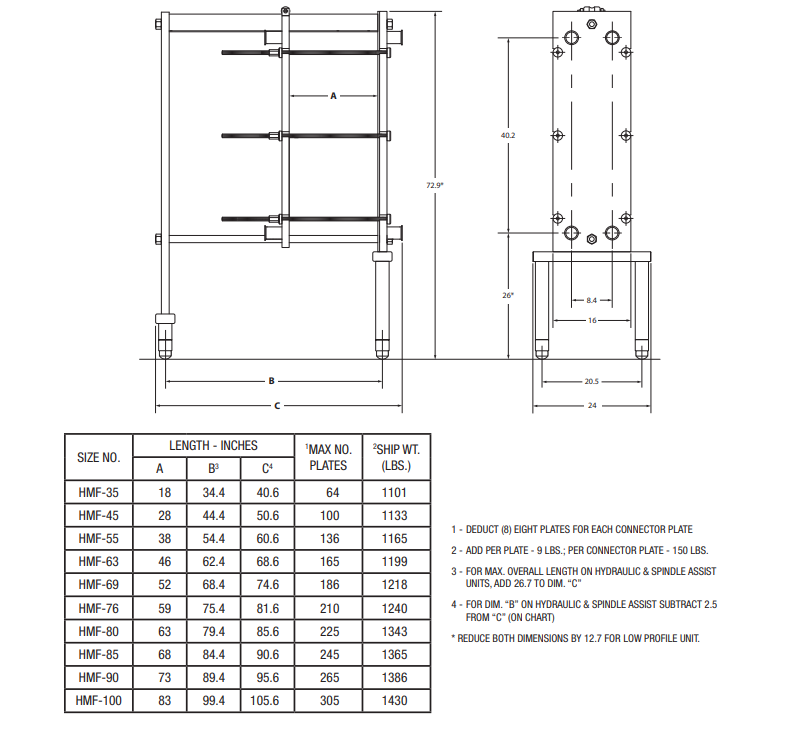

The Model HMF is the field-proven workhorse of the Chester-Jensen line. Countless installations worldwide offer testimony to the long-term efficiency and reliability of this fine unit. The HMF is compact, yet able to accommodate an extremely wide range of throughput capacities. Like its counterparts in this unique family of heat exchangers, the HMF owes its high performance characteristics to its “parallel flow” plate design. The heavy-gauge stainless steel used in the HMF plate, together with its inherent wide gap clearance design, make this versatile unit an obvious first choice in a myriad of applications including those involving viscous products.

STANDARD SPECIFICATIONS

A. FRAME CONSTRUCTION: Fixed and follower head are heavy carbon steel plate fitted with stainless steel inserts so that all wetted surfaces are stainless. Top guide bar is stainless and shaped to receive top eye of plate and connector plate rollers. Stainless lower bar ensures proper plate alignment and prevents lateral movement. End and base supports are formed carbon steel fabrications. Standard hi-profile design furnished with adjustable stainless steel ball feet at fixed head. Stainless steel, adjustable feet provided on end support for HMF-63 and larger units. Smaller units provided with fixed single point end support.

B. FINISH: All carbon steel surfaces are primed then painted with a special anti-rust coating of stainless steel pigment in a polyurethane vehicle.

C. CLOSURE: Plate stack is compressed by six (6) heavy-duty stainless steel tightening rods that pass through slots in fixed and follower heads. Brass nuts prevent galling.

D. CONNECTIONS: Fixed and follower heads are furnished with MPT, sanitary clamp, or IAMD bevel seat connections as required (2-½” standard).

E. CONNECTOR PLATES: Stainless steel, solid boss type, suspended roller. Furnished with MPT, sanitary clamp or IAMD bevel seat connections (2” standard).

F. PLATES: Gasketed, one-piece, single thickness 20 gauge Type 304 stainless steel die stamping, bright finish. 3.73 sq. ft. heat transfer surface per plate.

G. GASKETS: One-piece elastomers molded FDA approved materials selected on an application basis. Cemented in place and readily replaceable in the field.

H. INTERNAL PRESSURE: Maximum differential operating pressure 100 PSIG.

I. SHIPMENT: Unit usually shipped assembled and crated. Larger units require that plates be boxed separately.

J. WRENCH: Heavy-duty, malleable cast iron construction, ratchet type with reversing lever.

AVAILABLE OPTIONS

1. FRAME CONSTRUCTION:

- Fixed and follower heads fabricated solid Type 304 stainless steel plate. End and base supports are formed stainless steel fabrications. Blast finish (Model Suffix ‘S’).

- Standard hi-profile base supports may be furnished with adjustable stainless steel flanged feet in place of ball feet.

- Frames are available in lo-profile configuration with either adjustable stainless steel ball or flanged feet. Industrial units may be furnished with painted steel flanged feet at reduced prices.

- Single thickness, sectional, stainless steel protective shrouds, snap-on design for easy removal. Custom fitted.

2. FINISH: Carbon steel frames are available with Epoxy enamel paint finish. Choice of colors.

3. CLOSURE:

- Dual threaded tightening spindles to assist in proximity closing. Spindles and distance bars are Type 304 stainless steel. End supports are heavy-wall, mild steel fabrications with chrome-plated bronze spindle bushing inserts. Mild steel units have standard finish. ‘S’ Series units are clad with Type 304 stainless steel. Ratchet type spindle wrench included (Model Suffix ‘T’).

- Dual hydraulically powered tightening shafts to assist in proximity closing. Manually operated power source is housed in stainless steel enclosure, pre-piped and integrally mounted to end support Full-opening, hinged doors provide access for cleaning and storage facility for extension tubes and accessories. End supports are heavy-wall, mild steel fabrications with standard finish. ‘S’ Series units are clad with Type 304 stainless steel, blast finish (Model Suffix ‘H’). Note: Information on units with remote, electric power sources, Series ‘HR’, available upon request.

4. CONNECTIONS: Connector plates are available with 2-½” sanitary clamp, or IAMD bevel seat connections.

5. PLATES: Single thickness, die stamped plates are also available in Type 316 stainless steel.

6. GASKETS: Choice of gasket material, indicated by application. Buna (SBR) or ethylene propylene rubber (EPDM) FDA approved materials.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon