Low Noise Roller Chain

4 5 (1 evaluate)Category: Silent Chains

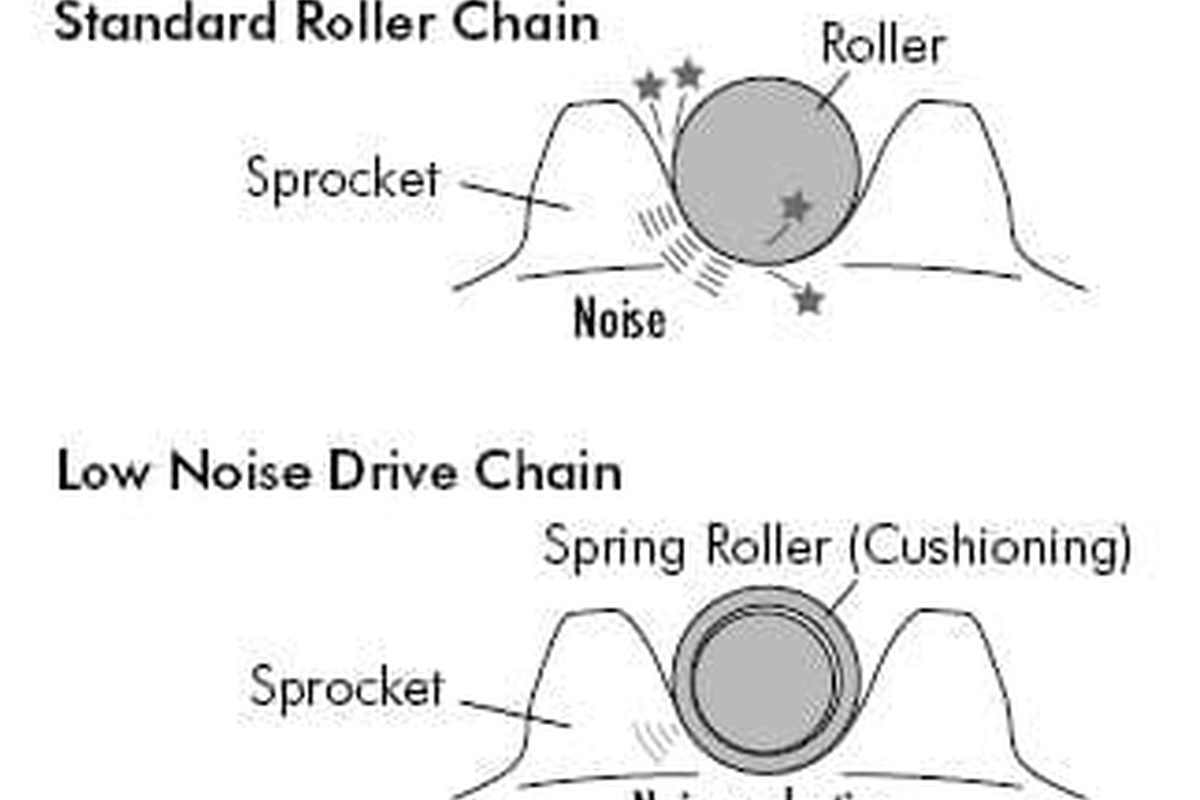

Low Noise Chains utilize spring rollers to reduce the impact between the chain and sprocket, resulting in a noise reduction of 6-8 dB compared to standard chains. These chains are ideal for noise-sensitive environments, such as printing and packaging industries, and help improve workplace comfort. They meet ANSI standards, ensuring compatibility with existing systems, and can save on installation costs by eliminating the need for additional noise insulation.

Low Noise Chains are designed to significantly reduce noise by utilizing spring rollers that minimize the impact between the chain and sprocket. This innovative design allows for a noise reduction of 6-8 dB, as confirmed by laboratory tests, making them an excellent alternative to standard roller chains.

Key Features of Low Noise Chains:

- Noise Reduction: Achieves a noise decrease of 6-8 dB compared to standard chains.

- Comfort Improvement: Ideal for noise-sensitive workplaces, enhancing employee comfort.

- Cost Savings: Eliminates the need for additional noise insulation devices, reducing overall installation costs.

- Compatibility: Built to ANSI standards, these chains are compatible with standard sprockets, allowing seamless integration into existing systems.

- Custom Specifications: Non-catalog specifications are available to meet unique operational requirements.

Ideal Applications:

- Printing and Packaging Machinery: Reduces noise pollution in high-speed production environments.

- Noise-Sensitive Work Environments: Suitable for any industrial setting where reducing noise levels is critical.

Low Noise Chains are particularly beneficial for industries like printing, packaging, and other sectors that prioritize a quieter operational environment. They provide an effective solution for noise reduction while maintaining compatibility with standard machinery components.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon