802 GT/ 805 GT

4 5 (1 evaluate)Category: Steel chains

The 802 GT / 805 GT steel chains from Movex's flattop chain series are designed for smooth and stable transportation of goods. Made from premium stainless steel with a rubber surface for enhanced grip, these chains are ideal for industries such as food processing, pharmaceuticals, and light manufacturing.

1. What are the 802 GT / 805 GT Movex Flattop Chains?

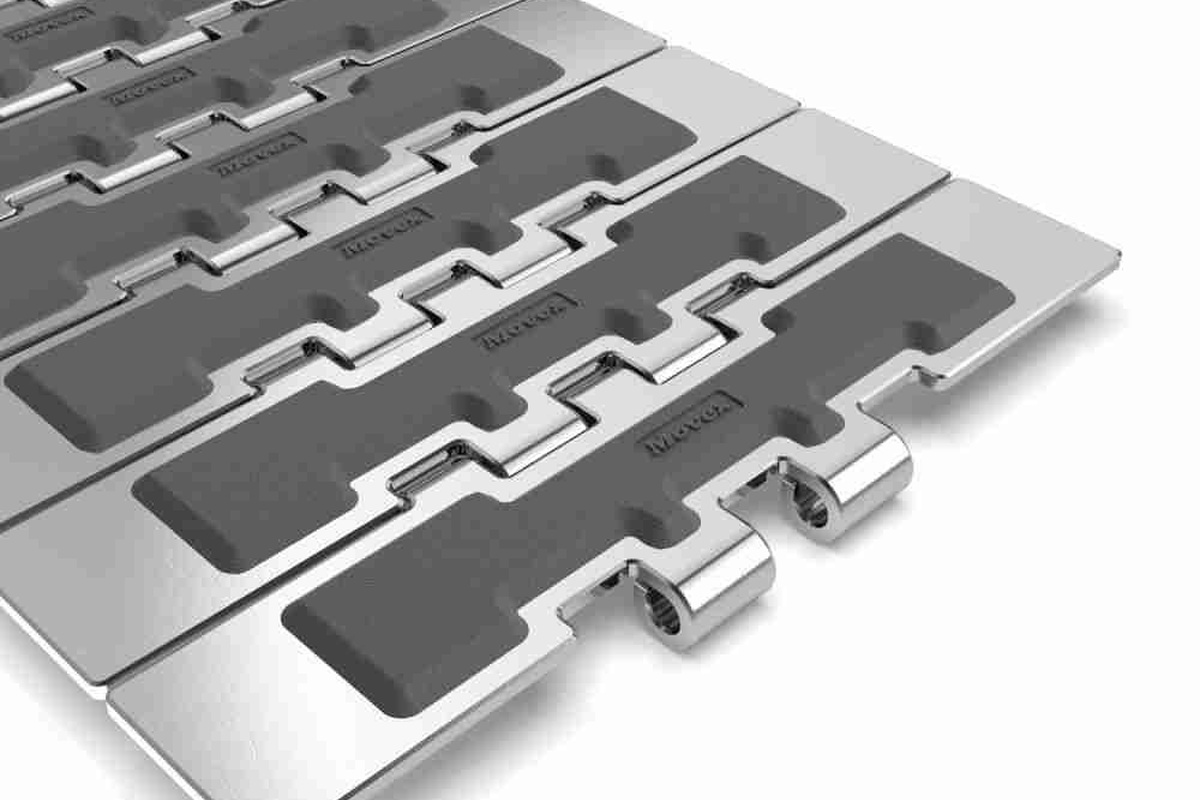

The 802 GT / 805 GT steel chains are high-performance conveyor chains made from high-quality stainless steel. Their rubber-coated surface enhances grip, ensuring safe transportation of goods, even on inclined or curved conveyor systems. These chains are designed for modern production lines with demanding requirements.

2. Key Features of the 802 GT / 805 GT Steel Chains

a. Premium Stainless Steel Construction

- Made from high-grade stainless steel for excellent corrosion resistance and durability.

- Suitable for harsh environments, including high humidity or exposure to chemicals.

b. Rubber Surface for Enhanced Grip

- The rubber-coated surface increases friction, preventing goods from slipping or shifting during transportation.

- Ideal for handling products requiring stability, such as bottles, cans, or food containers.

c. Flexible Hinge Design

- The hinge structure ensures smooth and efficient operation, reducing friction and enhancing performance on curved or complex conveyor layouts.

- Suitable for high-speed production lines.

d. Easy Maintenance and Installation

- Modular construction simplifies cleaning, assembly, and part replacement, reducing downtime and operational costs.

3. Practical Applications of the 802 GT / 805 GT Steel Chains

a. Food and Beverage Industry

- Processing Lines: Ideal for transporting fresh, frozen, or processed foods while maintaining hygiene standards.

- Packaging Systems: Efficiently handles the movement of food containers, bottles, or cans in automated packaging lines.

b. Pharmaceutical Industry

- Inspection and Packaging Lines: Provides secure handling of sensitive pharmaceutical products like blister packs, vials, and medical devices.

- Hygiene-Critical Processes: Stainless steel construction and rubber grip meet strict hygiene requirements and allow for easy cleaning.

c. Light Manufacturing

- Component Assembly Lines: Perfect for transporting electronic components, automotive parts, or small industrial devices.

- Automated Systems: Ensures smooth and reliable performance in high-speed production lines.

4. Benefits of Using the 802 GT / 805 GT Steel Chains

a. Enhanced Operational Efficiency

- The rubber surface ensures improved grip, minimizing the risk of goods slipping or falling during transportation.

b. Cost-Effective Solution

- Durable materials reduce maintenance and replacement costs, ensuring long-term savings.

c. Improved Goods Safety

- The robust design protects goods from damage while ensuring secure transportation.

d. Versatility

- Suitable for various industries and conveyor configurations, from food and pharmaceuticals to light manufacturing.

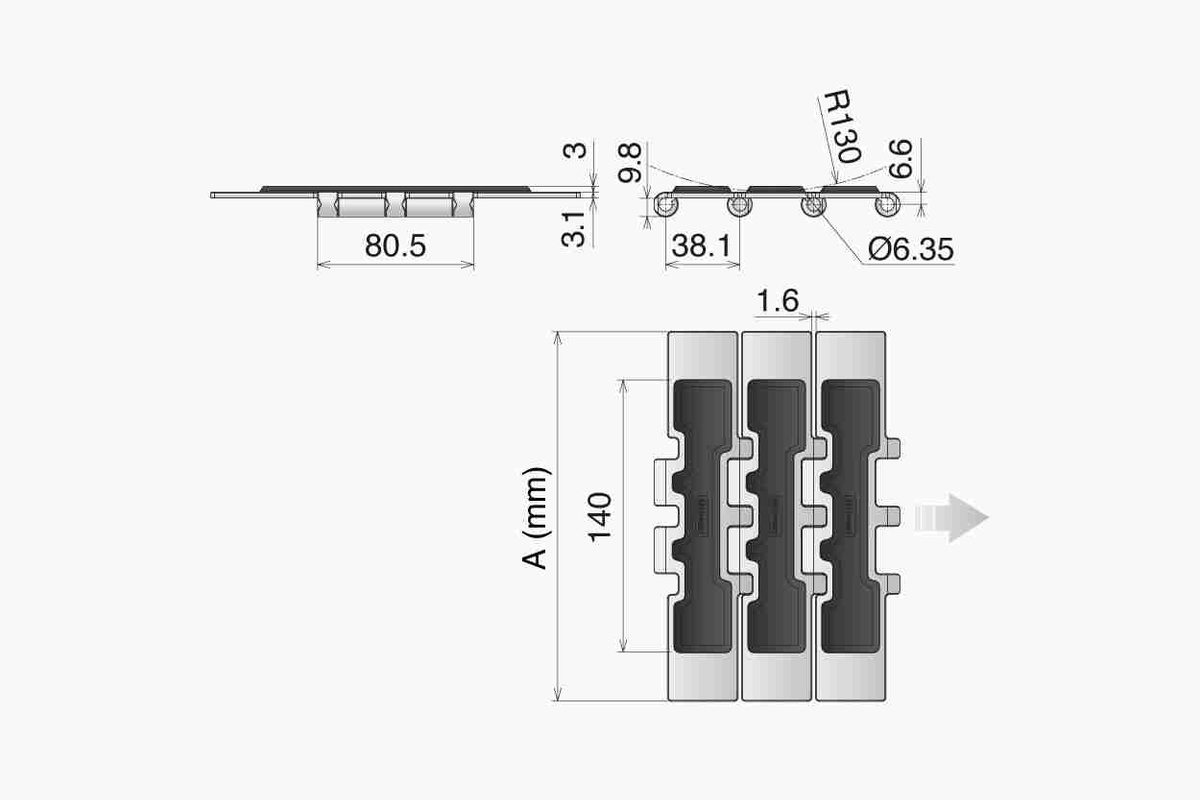

5. Technical Specifications

| Model | Material | Width (mm) | Max Load (N) | Key Applications |

|---|---|---|---|---|

| 802 GT W82 | Stainless steel + rubber | 82 | 2,800 | Food processing, packaging lines |

| 805 GT W114 | Stainless steel + rubber | 114 | 3,200 | Pharmaceutical inspection lines |

| 805 GT W152 | Stainless steel + rubber | 152 | 3,800 | Component assembly, light goods |

6. Comparison with Other Movex Flattop Chains

| Criteria | 802 GT / 805 GT Chains | 8811 TAB Chains | 552 FG Chains |

|---|---|---|---|

| Surface Grip | Excellent | Good | Moderate |

| Corrosion Resistance | Excellent | Excellent | Good |

| Key Applications | Food, pharmaceuticals | Light manufacturing | Light manufacturing |

7. Installation and Maintenance

a. Installation Guidelines

- Ensure proper alignment of chain links to prevent misalignment or excessive wear.

- Use compatible sprockets and guide rails to optimize conveyor performance.

b. Maintenance Tips

- Regular Cleaning: Keep the rubber surface and chain links clean to remove dirt and grease, ensuring smooth operation.

- Routine Inspections: Check for wear or damage on the links and rubber surface, replacing components as needed.

- Timely Replacements: Replace damaged parts promptly to avoid disruptions in production.

8. Conclusion

The 802 GT / 805 GT steel chains from Movex's flattop chain series are reliable and versatile solutions for modern conveyor systems. With their durable stainless steel construction, rubber surface for enhanced grip, and flexible hinge design, these chains enhance operational efficiency, reduce maintenance costs, and ensure safe transportation of goods. Investing in the 802 GT / 805 GT steel chains guarantees improved performance and long-term savings for your production lines.

.png)

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon