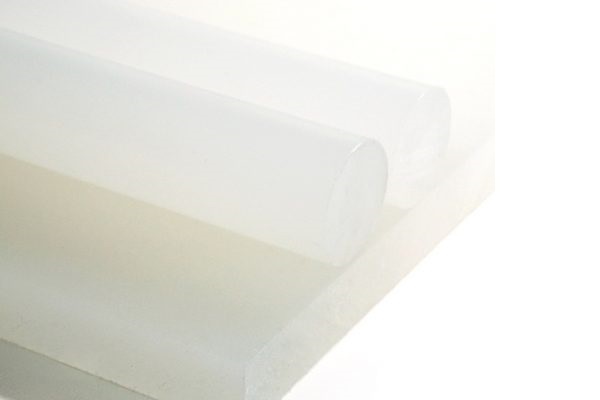

UHMWPE

4 5 (1 evaluate)Category: Engineering Plastics

Common Applications of UHMWPE – The Industrial Powerhouse Material

Ultra-High Molecular Weight Polyethylene (UHMWPE) stands as one of the most formidable materials in industrial engineering. Known for its extreme durability, superior wear resistance, and exceptional chemical resistance, UHMWPE is a key asset in heavy-duty applications across multiple sectors. While it does not perform well in high-temperature environments, its unmatched performance in abrasion resistance, impact strength, and low friction make it the material of choice for industries demanding reliability and longevity.

Let’s explore the most common and critical applications of UHMWPE across a range of industrial environments.

1. Food Processing Industry

In the highly regulated food processing industry, UHMWPE is indispensable. With FDA approval, its non-toxic nature and low friction properties make it the ideal material for fabricating components such as bearings, gears, chute liners, and wear strips. These parts operate smoothly, reducing downtime and improving overall production efficiency, while ensuring easy maintenance and sanitation in high-demand environments.

2. Material Handling and Packaging

For material handling and packaging operations, UHMWPE is synonymous with durability. From anti-static chute liners to wear strips and bearings, components manufactured from UHMWPE sheets enhance the longevity of equipment while minimizing maintenance intervals. Its ability to withstand friction and wear under constant movement makes it a valuable asset in environments where efficiency and uptime are critical.

3. Conveyor Systems

Conveyor systems across industries benefit significantly from UHMWPE due to its superior sliding properties and resistance to wear. It is used in key components such as wear strips, chain guides, and gears. UHMWPE’s low friction coefficient ensures smooth operation and long service life, even in environments where continuous movement and friction are a constant.

4. Marine Applications

The marine environment demands materials capable of withstanding constant exposure to water, salt, and wear. UHMWPE excels in this area, being used in dock fenders, boat components, handles, and protective covers. Its resistance to moisture absorption and corrosion makes it the perfect choice for both structural and functional applications in marine environments.

5. Waste Water Treatment Facilities

In wastewater treatment facilities, materials must endure harsh chemicals and abrasive conditions. UHMWPE components such as paddles, bearings, scraper blades, and chute liners perform exceptionally in this demanding setting. Its chemical resistance ensures longevity, even when exposed to the most aggressive substances, making it indispensable for long-term, maintenance-free operation.

6. Infrastructure and Construction

In construction and infrastructure projects, UHMWPE is chosen for its impact resistance and durability. Whether it's sliding pads, bearings, or heavy-duty wear strips, UHMWPE components require minimal maintenance and deliver exceptional lifespan, even under heavy loads and constant stress. Its easy installation and long service life make it a preferred material in high-demand construction applications.

7. Automotive Industry

While UHMWPE may not be suited for high-temperature environments, it plays a critical role in automotive components requiring durability at room temperatures. Door panels, seating mechanisms, and various interior components benefit from UHMWPE’s wear resistance and impact strength, offering a lightweight, highly durable alternative to traditional materials, contributing to vehicle efficiency and longevity.

8. Advanced Protective Gear

In the realm of personal protective equipment (PPE), UHMWPE stands out due to its high impact strength and lightweight properties. It is commonly used in body armor, where it effectively absorbs and disperses energy, offering a superior balance of protection and comfort to the wearer, making it an essential material in the production of advanced protective gear.

9. Sporting and Leisure Applications

UHMWPE’s inherent durability and wear resistance extend beyond heavy industries into the sporting and leisure sectors. It’s used in recreational vehicles such as snowmobiles and ATVs, enhancing the performance, reliability, and lifespan of critical components, especially those subject to constant friction and wear.

10. Other Industrial Applications

Outside of these specific uses, UHMWPE proves its versatility across a broad spectrum of industrial applications, including:

- Truck bed liners: Known for their durability and non-stick properties, UHMWPE liners ensure smooth loading and unloading of materials.

- Plastic rods and sheets: Available in a wide range of sizes, UHMWPE is easily fabricated into custom parts for gears, bearings, and specialized machine components.

Performance Characteristics of UHMWPE

UHMWPE is celebrated for its unmatched toughness and durability in extreme conditions. Its low friction coefficient makes it highly wear-resistant, offering excellent sliding capabilities crucial for applications involving high levels of movement and mechanical stress. Additionally, its chemical resistance allows it to perform reliably in environments where exposure to corrosive substances is inevitable. Its low moisture absorption ensures dimensional stability and a long lifespan, even in wet or humid conditions. UHMWPE is easily machined and fabricated, enabling the production of custom parts that meet the exact specifications of industrial applications.

Conclusion

When it comes to demanding industrial environments, UHMWPE proves to be a game-changer. Its unique combination of strength, durability, and resistance to chemicals and water makes it the go-to material for a variety of industries. Whether you’re considering it for new applications or replacing less durable materials, UHMWPE offers clear, long-lasting advantages. For those seeking top-tier engineering plastics, UHMWPE strips and sheets from trusted suppliers like Okulen® offer a high-performance solution that meets stringent industry standards.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon