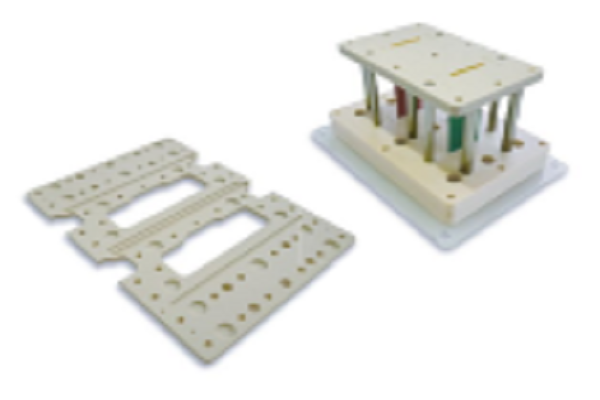

TPS-TOPFINE R1OOO

4 5 (1 evaluate)Category: TopFine

[Composite Engineering Plastic Plate for Precision Micro Hole Drilling Processes]

■ Ultra dimensional stability, stiffness, and precision machinability

TOPFINE® R1000 was jointly developed by Toyo Plastic Seiko Co., Ltd. and the resin manufacturer Toray Industries, Inc. This material boasts excellent dimensional stability and is specially designed for precision hole drilling.

Producing holes with a diameter of several tens of microns in conventional super engineering plastic is associated with various problems caused by flash, post-processing, probe pin errors, and other factors.

So far, only a limited number of wholly aromatic polyester resins could be used for plates and other parts requiring ultrafine holes.

Special resin treatment and original molding technology make TOPFINE® R1000 a super engineering plastic that largely elimi-nates flash related problems during precision machining.

Because of composition using the PPS resin with excellent dimensional stability as the base and also containing a high percentage of different kinds of special inorganic particles, TOPFINE® R1000 can be described as a compound super engi-neering plastic resin material.

It not only boasts improved machinability and boring workability but also has excellent stiffness on a par with fiber- reinforced resin which is notoriously difficult to cut.

■ Features

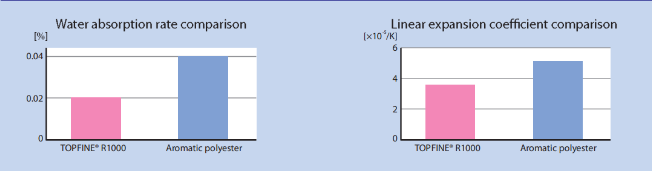

- Low water absorption rate and low linear expansion coefficient result in high dimensional stability.

- Highly suitable for machining, minimal flash when produc¬ing ultra-fine holes.

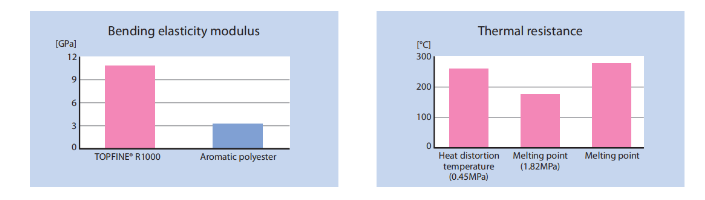

- Best elasticity of unreinforced resin.

■ Ultra dimensional stability

■ Outstanding stiffness

With the high elastic modulus of 10 GPa for TOPFINE® R1000, it is possible to prevent the distortion or deformation at the time of usage even if it is processed very thin.

Due to its stiffness and plastics good workability. TOPFINE® R1000 can be used in place of stiff material such as ceramics, bakelite and glass-reinforced expoxy which are hard to machine.

■ Thermal resistance

TOPFINE® R1000 has a thermal resistance of melting point at 278°C, heat distortion temperature at 260°C (0.45 MPa) and 175°c (1.82 MPa), that is in effect sufficient for testing tool applications.

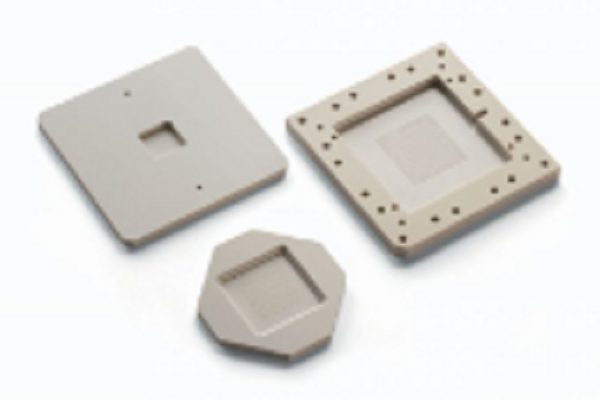

■ Suitable for Precision Micro Hole Processing

TOPFINE® R1000 is eminently suited for high-precision machin-ing. Parts with 50-micron diameter holes have been successfully produced. (Processing result will differ depending on processing conditions, shape, etc., so perform sufficient advance evaluations.)

■ Precautions for machining and use

Because TOPFINE® R1000 has high hardness for a resin material, drill selection, blade sustainability and other factors are critical. Due to its composition, the material has little elongation and can get chipped easily. This should be taken into consideration du ring the parts design process.

Since the glass transition temperature is lower than the aromatic polyester, usage under high loads and high temperatures must be based on thorough tests prior to implementation.

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon