TPS-TOPFINE R8220

4 5 (1 evaluate)Category: TopFine

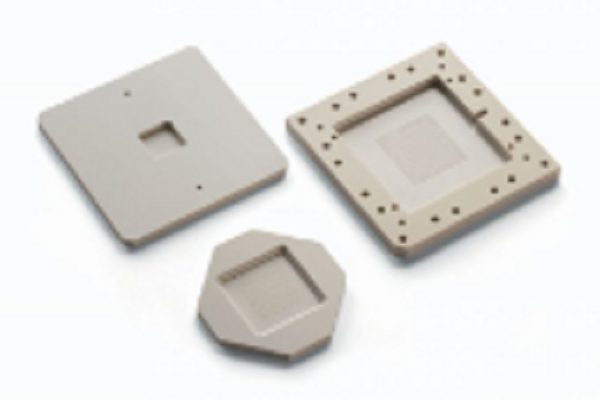

[Composite Engineering Plastic Plate for Precision Micro Hole Drilling Processes]

■ Ultra precision machinability, high toughness

Problems such as flash occurred when ultra fine drilling is performed on conventional super engineering plastic materials. To resolve this problem, TOPFINE® R1000 with enhanced cutting and drilling ability was developed and sold with high dimensional stability using the PPS resin as a base, and containing various special inorganic particles.

However, with the further requirement of enhanced machining characteristics, TOPFINE® R8220 was newly developed, with enhanced toughness by using the PEI resin as a base, and equivalent drilling ability as theTOPFINE® R1000.

■ Features

- Toughness is enhanced by using PEI resin asthe base.

- Highly suitable for machining and there is minimal flash when producing ultra-fine holes.

- 300 mm square size with thickness of 3 to 15 mm can be provided by our original molding technology.

■ Usage

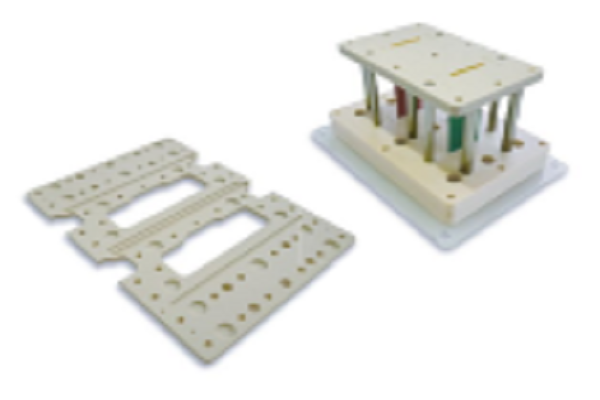

- IC parts, precision parts transportation tray

- Semiconductor device parts transportation tray

- Transportation equipment roller

- Parts inside the clean room

■ Precision micro hole processing

TOPFINE® 8220 is eminently suited for high-precision machining. Parts with 200 and 80-micron diameter holes have been successfully produced. (Processing result will differ depending on processing conditions, shape, etc., so perform sufficient advance evaluations.)

.png)

AAdministratorsQTV

Welcome. Feel free to leave a comment, we will respond soon